Passive House Principles and Components in New Zealand

Passive homes in New Zealand are growing in popularity – and rightfully so because improving construction standards in New Zealand will always be of benefit. Homes built utilising the new Passive House standard have appeared around Auckland, Christchurch, Wellington and Queenstown.

This article will serve as an introduction into the world of Passive house building design and construction, covering sustainable and green design, air changes, passive house certified components and more.

What is a Passive House?

The Passive House standard is a world-leading building standard which is centered around energy efficient construction. Passive House design and construction means the house will require minimal energy consumption to achieve a comfortable temperature year-round, this includes all aspects of heating and cooling. In addition to providing comfort with minimal heating and cooling, the Passive House construction standard is designed to protect the building structure for long-term occupancy.

The standard can be applied to both residential buildings along with commercial premises. Various criteria must be met in order for the dwelling to be listed as an officially certified passive house. Online databases exist where you can search for certified passive house buildings, including various projects which included products by STIEBEL ELTRON. Many people are deciding to construct a living space which won't meet the exact criteria, but instead with a passive house planning package which fits into their budget.

Space Heating Energy Demand

Heating energy must not exceed 15 kWh per square metre per year (or 10 W per square meter of living space). Small demands for heating can easily be met with the installation of convection electric panel heaters in open rooms and electric undertile heating for bathrooms. If further heating is required, hydronic heat pump solutions are often recommended.

Space Cooling Energy Demand

In areas where cooling is required, energy consumption to cool the living space is very similar to the energy consumption of heating energy, adjusted to allow for dehumidification. If a hydronic heating solution is included in the building design, it is recommended to select an inverter-driven air source hydronic heat pump, which can provide both heating and cooling.

Indoor Air Changes, Airtightness and Ventilation Systems

A maximum of 0.6 air changes per hour at 50 Pascals pressure (ACH50). Having such a low amount of air changes has the benefit of reducing the amount of heating and cooling energy consumption. However it also means mechanical ventilation with heat recovery is required to bring in fresh air and maintain healthy indoor air quality. Airtightness and ventilation is explained in greater detail below.

Energy Efficiency and Renewable Primary Energy Demand

The total energy consumption for all domestic applications, including room heating, water heaters, ventilation and domestic electricity must not exceed 60 kWh per square metre of treated floor per year.

Thermal Comfort

Thermal comfort levels must be achieved in the entire living space and maintained year-round, with not more than 10% of the hours over 25 °C for a given year.

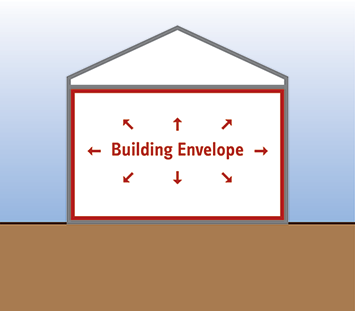

Building Envelopes and Energy Savings

With implementation of the concepts above, a building envelope is created which separates the interior from the exterior. This separation acts to keep the interior at a comfortable and stable temperature, while the outside temperature and climate fluctuates depending on environmental weather conditions.

The building envelope for passive house standard designed buildings mostly consists of insulating all around the building, in addition to a final air-tight layer because most insulating material is not airtight. While construction methods, materials and technology may change and advance, the requirement for both insulation and an airtight layer will always remain.

The ability of the building's envelope is directly linked to the potential for energy savings, this is known as minimisation. The greater effectiveness of the insulation and airtight layer will minimise the required heating and cooling energy, increasing overall energy savings.

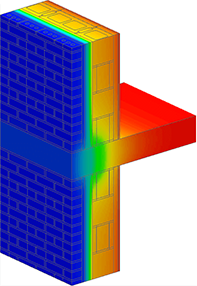

Thermal Bridges

Thermal Bridges are an important concept relating to design for the Passive House building standard. Thermal Bridges are defined as thermally weak points or interruptions in the building envelope which cause energy to be lost through heat losses. The heat losses from thermal bridges will cause lower interior temperatures of the surrounding areas. These lower temperatures cause moisture to build up and promote mould growth, impacting on the health and structural integrity of the building.

Arguably the biggest consideration for thermal bridges in building design are the windows of the dwelling. Windows traditionally in New Zealand have been thin and single glazed, which promote heat losses from the interior to the outside.

Passive house buildings are ideally paired with double glazed windows which provide greater insulation. However, not all double glazed windows are made equal. Thermally broken double glazed windows offer greater performance through insulation, minimising heat losses.

Thermal bridges can also include ceiling junctions, balconies, corners, verges and eaves. Thermal Bridges must be considered and a higher level of thermal protection added during the design phase.

Air Tightness and the Blower Door Test

When building a green home and following Passive House principles and criteria, air tightness can present the challenge of bringing fresh air into the building envelope. The maximum permitted number of air changes in an hour must not exceed 0.6. Air changes in the building envelope are measured with a blower door test. Low numbers of air changes will result in less heat energy transferred outside, ensuring stable levels of thermal comfort.

Performing a Blower Door Test

The process of performing a blower door test starts with the calculation of the entire volume in the building envelope this is used to calculate air leaking values later. The building is then prepared by sealing all windows and opening all internal doors.

A blower door is then attached to the entrance of the dwelling. The blower door is essentially a fan mounted on an airtight membrane. The blower door is used to pressurise the envelope so that pressure values can be recorded and any leaks can also be found.

Passive House Components

Along with defining the building standard, Passive House offers an independent testing service for components designed to be used in commercial and residential building implementing the Passive House building standard. Passive House certified components are independently tested and certified to ensure that you are receiving components which fit the criteria of greatest quality control, high performance and energy efficiency. As a general rule, Passive Certified components are two to three times more efficient than the otherwise corresponding products which are often used.

Once a component has been certified by the Passive House Institute, the manufacturers and retailers of said product are able to display the “Certified Componentâ€, notifying everyone of the performance, quality and efficiency of their product. The certification has recently been expanded to include climate-based certifications for product performance. The three certifications are “warm, temperature climate (phA+)â€, “cool, temperate climate (phB)†and “hot climate (phA)â€.

Ventilation

Arguably the most important component in your Passive House build, it is vital to select a heat recovery ventilation system which is certified for its performance and quality. The LWZ 180 is an ideal example of a certified ventilation system, boasting quiet yet exceptional performance.

Click here to view STIEBEL ELTRON's range of heat recovery ventilation.

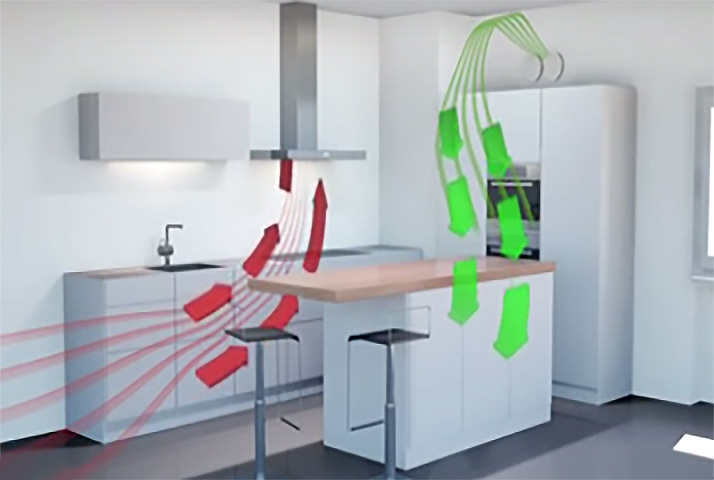

Range Hoods/Kitchen Extractors

Airtightness in modern well-built homes can create unique challenges, such as the extraction of air while cooking with range hoods or kitchen extractors. The challenge being that extracting kitchen air will create negative pressure in airtight homes. There are two solutions for using range hoods, either opening a well-sealed valve to allow air to enter into the building envelope, or recirculating extracted cooking air from the rangehood through air filters and then back into the building envelope.

Passive House High Rise Buildings

New Zealnd is currently witnessing a shift to apartment living, predominantly seen in major cities like Auckland and Wellington. Passive House Towers are more comfortable with lower living expenses for their residents.

Passive House Retrofit

While posing a challenge, it is possible to upgrade your house and retrofit Passive House standard. It is claimed that by retrofit applications have reduced their heating demand by up to 90%. Existing structures may cause problems with thermal bridges, so official certification may be a challenge. However keeping the Passive House principles in mind whilst planning and designing a renovation can result in increased efficiency and performance.